The methods and technologies for utility installation and rehabilitation span a range of techniques, each with specific applications, purposes, and requirements.

Open-Trench/Open-Cut Method involves digging a large trench to install utilities, where tracer wire is placed alongside the utility in the trench. This method provides a clear, visible path for locating utilities after burial but requires significant surface excavation and disruption. It is flexible and suitable for various utilities, though it can be time-consuming and costly due to the need for extensive excavation and surface restoration.

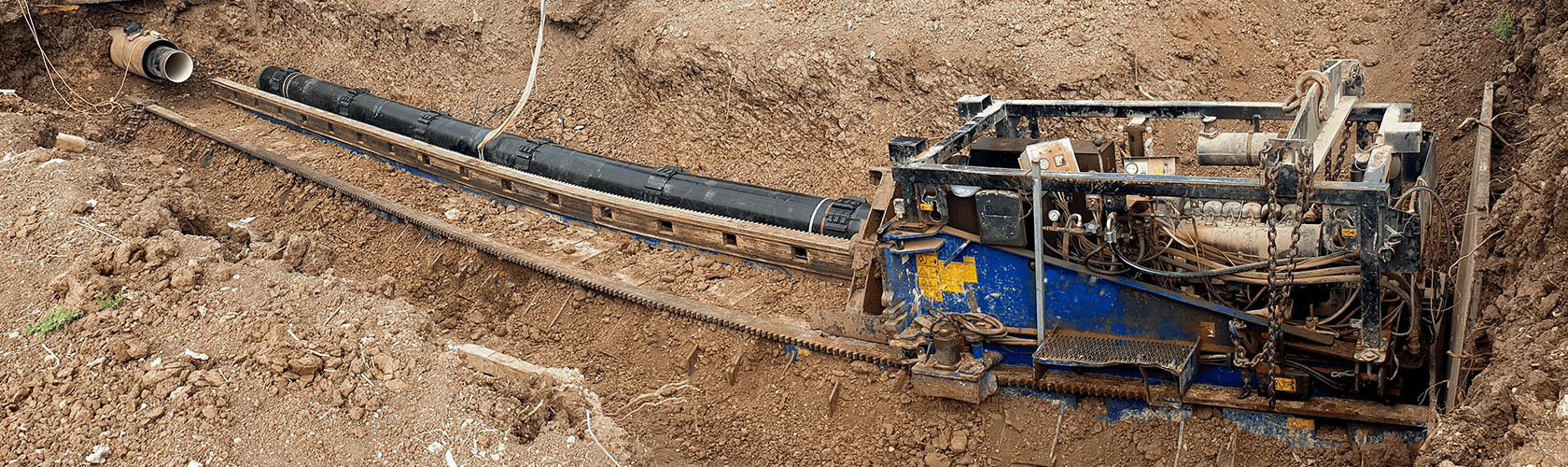

Auger Boring employs a helical drill bit to create a borehole for utility installation, with tracer wire placed alongside the utility in the borehole or conduit. This trenchless method minimizes surface disruption and is ideal for short, shallow boreholes. The equipment is generally simple and cost-effective, but the method may be less effective in hard rock or unstable soils and is best suited for smaller diameter and shallower installations.

Directional Boring utilizes horizontal directional drilling (HDD) to create a path for utility installation. Tracer wire is placed alongside the utility during the drilling process. This trenchless technology minimizes surface disruption and is suitable for long distances and larger diameter installations. It offers flexibility in various soil conditions but requires specialized equipment and expertise, which can make it more costly.

Microtunneling uses a microtunnel boring machine to install small-diameter pipes or cables with tracer wire placed inside the pipe or conduit or alongside it in the microtunnel. This method provides precise control with minimal surface impact and is ideal for urban environments or sensitive areas. However, it involves high initial costs and complex machinery and is best suited for small-diameter installations.

Pipe Bursting replaces old pipes by breaking them and pulling new pipes through the same path, with tracer wire attached to the new pipe. It is a trenchless method that minimizes surface disturbance and is effective for upgrading or rehabilitating existing pipelines. This method is versatile but requires the old pipe to be clear of obstructions and the new pipe’s path to accommodate the new utility.

Sliplining involves inserting a smaller pipe into an existing larger pipe, with tracer wire installed in the annular space between the old and new pipes or along the new pipe. This trenchless technique extends the life of existing infrastructure and requires less excavation than open-trench methods. However, it reduces the diameter of the original pipe and is limited by the condition and size of the existing pipe.

Casing Installation installs a larger pipe or casing first, then pulls a smaller utility pipe through, with tracer wire placed inside the casing or secured outside. This method offers additional protection for sensitive or critical utility lines and is effective in high-traffic areas. The complexity and cost can be higher due to the need for both casing and utility pipe installations.

Blowing-In Method uses equipment to blow utilities into a pre-dug hole or conduit, with tracer wire fed through the conduit or alongside the utility. This method is efficient for inserting smaller utilities into existing conduits with minimal disruption, though it is limited to certain utility types and conditions.

Plow-In Method creates a slit in the ground for placing utilities using a plow, with tracer wire placed in the slit alongside the utility. It reduces surface impact compared to open-trench methods and is quick for small-scale installations but is limited by soil conditions and utility size.

Light Boring Method uses boring equipment to create a small hole for utility placement, with tracer wire placed alongside the utility. This method minimizes excavation and is effective for shallow, small-diameter installations but is not suitable for large-diameter or deeper installations and is limited by soil and rock conditions.

Inside Conduit Method installs utilities inside protective conduits, with tracer wire placed inside the conduit alongside the utility. This method provides additional protection and allows for future maintenance, though it may involve higher costs and complexity due to the need for both conduit and utility installations.

Each method has its advantages and limitations, making it essential to choose the appropriate technique based on the specific requirements of the project, including soil conditions, utility type, and desired level of surface disruption.